Read Time: 8 minutes

5 Key Takeaways for Business Owners:

Inventory Chaos Costs Money — Manual processes lead to overselling, wrong shipments, and wasted time that directly impact your bottom line

Automation Delivers Measurable ROI — Modern WMS systems achieve 99% inventory accuracy and reduce fulfillment errors by up to 70%

It's Not Just for Big Companies — Small and medium businesses are driving 20% annual growth in the WMS market with accessible solutions

Real-Time Visibility Transforms Operations — Know exactly what you have, where it is, and when it's moving at all times

Integration Is Everything — The best systems connect your warehouse with ERP, shipping, and e-commerce platforms for seamless operations

Got your online store running? Products listed, orders coming in, marketing finally paying off? Great start.

But then reality hits:

- You oversell an item that's already out of stock

- A customer gets the wrong item (again)

- Your team wastes hours hunting through the back room for inventory

This story plays out every day. Eventually, manual processes and basic eStore features just can't keep up. That's when warehouse management becomes crucial — and it's not just for massive retailers anymore.

Let's dive into how a solid warehouse management system (WMS) can save your business time, money, and a lot of headaches.

How Warehousing Has Changed

The warehousing world looks completely different than it did just a few years back. What used to be simple storage rooms with products stacked on shelves have become sophisticated, data-driven operations covering millions of square feet. E-commerce growth, always-on consumers, and omnichannel fulfillment have completely changed how businesses think about inventory.

The numbers back this up: the global warehouse management system market hit USD 2.88 billion in 2024 and should grow at 19.9% annually through 2030. This explosion reflects how fundamentally business operations have shifted. In fact, 87% of warehousing and retail decision-makers said they're either expanding warehouses or planning to by 2024.

Today's warehouses are smart, automated, and adaptable. They're built not just to store products, but to move them efficiently from dock to doorstep with minimal human touch.

What Actually Is a Warehouse Management System?

Think of a warehouse management system as your inventory's command center. It's software that tracks every item flowing through your business — from when it arrives at your dock to when it ships to customers.

But it goes way beyond just tracking. A WMS gives you complete visibility of your inventory lifecycle. It knows exactly where every product sits on your shelves, instantly checks availability when orders come in, and can optimize how your team picks and packs orders.

Here's what makes it powerful: when a customer orders something, your WMS immediately knows if it's available and marks it ready for packing. No more manual checking, no more overselling, no more angry customers getting "out of stock" emails after they've paid.

The Automation Advantage: Why Manual Processes Are Holding You Back

The primary game-changer with warehouse management systems is automation. Those routine tasks that eat up your team's time — receiving inventory, processing orders, updating stock levels — can all be automated.

The impact is measurable. According to recent industry research, automated warehouses achieve 99% inventory accuracy (a 76% improvement over manual systems), reduce labor costs by 3% annually (a 36% improvement), and consistently ship within one day of order placement (a 40% improvement). Automated picking systems alone can reduce fulfillment errors by up to 70%, saving money while dramatically improving customer satisfaction.

Digital cycle counts replace time-consuming manual inventory checks, giving you real-time accuracy without the labor costs. Your system can capture data through barcode scanning, voice recognition, and optical character recognition, making the entire process faster and more accurate.

But here's where it gets really interesting: your WMS doesn't just track what's happening now — it learns from patterns. By analyzing which products move fastest, the system can help you optimize your warehouse layout. Fast-selling items get placed closer to packing areas. Slow movers get repositioned to make room for higher-margin products.

Beyond Storage: Aligning Your Entire Supply Chain

Advanced warehouse management systems don't operate in isolation. They connect your upstream procurement with downstream fulfillment, creating a seamless flow of information across your entire supply chain.

This integration provides real-time visibility of inventory that's on-hand, on-order, and in-transit. You'll know exactly what's coming, what's available, and what's already committed to orders. This level of visibility prevents both stockouts (running out of popular items) and excess inventory (tying up cash in slow-moving products).

The result? Better cash flow, happier customers, and fewer headaches for you and your team.

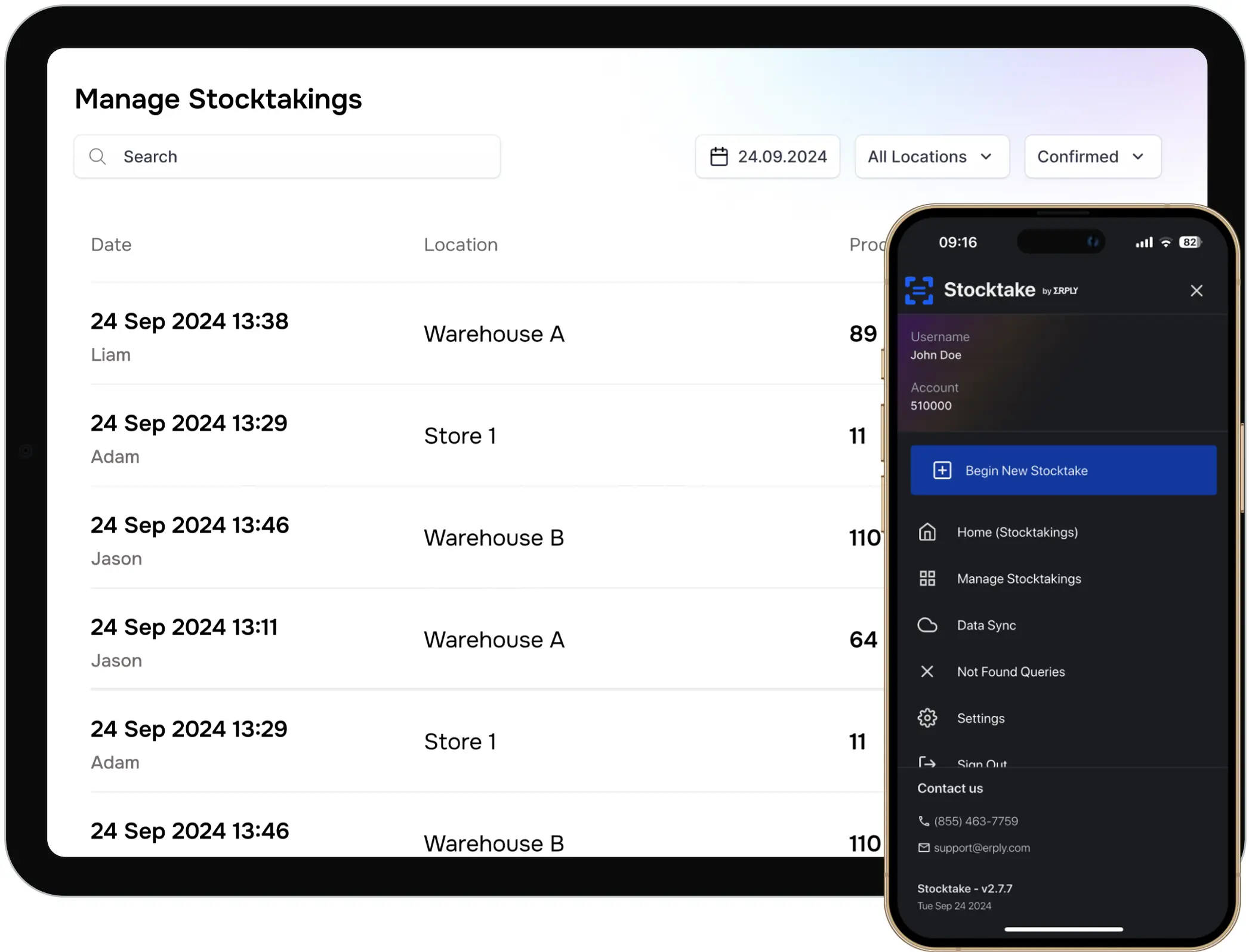

The Mobile Revolution in Warehouse Management

Modern WMS solutions come with user-friendly mobile applications that work with handheld devices. This means your team can track transactions, update inventory, and manage tasks from anywhere in your warehouse. No more running back to a desktop computer to update the system — everything happens in real-time, on the go.

Making the Investment: It's Not Just for the Big Players

Here's the truth that many growing businesses miss: warehouse management systems aren't just for Amazon-sized operations. The U.S. warehouse management system market was valued at USD 783.0 million in 2023 and is projected to grow at a CAGR of 20.0% from 2024 to 2030, with much of this growth driven by small and medium-sized businesses finally recognizing the need for systematic inventory management.

In 2024, flexible infrastructure technologies such as mobile robotics and automated guided vehicles (AGVs) are leveling the playing field, making sophisticated warehouse automation accessible even to businesses that previously couldn't afford capital-intensive automation projects.

If you're dealing with inventory chaos, manual processes that don't scale, or customer service issues related to fulfillment, you're already paying the cost of not having a WMS. The question isn't whether you can afford to implement warehouse management — it's whether you can afford not to. Every oversold item, every mispicked order, every hour spent manually tracking inventory is costing you money, time, and customer trust.

Real-World Solution: How Erply WMS Works

Let's get practical. While we've covered the theory and benefits of warehouse management systems, you might

wonder what this actually looks like day-to-day. The Erply Warehouse Management System provides a

solid example of how modern WMS solutions tackle the exact problems we've been discussing.

Erply WMS brings structure, real-time visibility, and streamlined operations to warehouses of all sizes. From receiving shipments to fulfilling orders, everything gets tracked and optimized. Whether you run an e-commerce store, retail chain, or wholesale distribution center,

Erply's warehouse

solution helps you scale without the usual inventory headaches.

Who This Helps Most

- Warehouse managers who need oversight and control

- Inventory specialists who require accuracy and visibility

- Logistics and fulfillment teams who need efficiency

- E-commerce, retail, wholesale, and manufacturing businesses of all sizes

Problems It Actually Solves

Remember those pain points we started with? Erply WMS directly addresses:

- Inaccurate inventory levels — Real-time tracking eliminates guesswork

- Shipping mistakes and delays — Barcode scanning and verification prevent errors

- Lost or misplaced stock — Every item has a tracked location

- Manual paperwork overload — Digital workflows replace paper trails

- Disconnected systems — Integrations with ERP, shipping, and inventory tools

Getting Started: Setup to Success

The setup process is straightforward:

- What You Need:

- Admin rights in your Erply account

- Desktop for back office work

- Android scanner device for mobile warehouse use

- Label printer for barcode generation

- Installation:

- Head to the Erply App Store and grab two components:

- Erply WMS App — for daily warehouse operations

- Erply WMS Settings App — for configuring workflows and layouts

- Setup:

- Map your warehouse layout: define aisles, shelves, and bins

- Assign user roles based on what people actually do

- Configure workflows for receiving, picking logic, and shipping integrations

Features That Actually Matter

These are the features that make warehouse life easier — for everyone from the floor to the office:

- Know Where Everything Is — Track every product in real time: quantity, bin location, lot number, serial number, expiry date, and status. No more treasure hunts in the back room.

- Smart Receiving Process — Scan items when they arrive, verify against purchase orders, and automatically assign items to the best locations based on your warehouse layout and picking patterns.

- Better Picking & Packing — Cut picking errors with smart routing and mandatory barcode scanning. The system guides workers through efficient paths, saving time and preventing mistakes.

- Handle Returns Properly — Process returns through a clear workflow: approval → receive → inspect → restock or discard. Turn chaos into a smooth operation.

- Useful Data Insights — Get actionable reports on picking times, stock turnover, fulfillment rates, and operational efficiency. Quick and exact warehouse management becomes possible with real data.

- Works With Your Existing Tools

- Shipping partners: DPD, Smartpost, Venipak, Omniva, ShipEngine

- ERP & Finance systems: NetSuite, Telema, Docura

- Hardware: Label printers and barcode scanners

What Daily Operations Look Like

Here’s how a typical day flows with Erply’s warehouse realization:

- Receiving Goods (With Purchase Order):

- Log in → Select "Products In"

- Choose the purchase order

- Scan product barcodes for verification

- Confirm quantities match

- Submit and close the receipt

- Picking Sales Orders:

- Log in → Select "Products Out"

- Choose the sales order to fulfill

- Go to the bin location

- Scan and confirm the right items

- Complete the order and print shipping labels

- Moving and Organizing Stock:

- Access "Place Products" function

- Select "Move from Receiving"

- Scan the product → assign to best bin → confirm placement

What Actually Works

- Do regular cycle counts to keep things accurate

- Scan barcodes for everything — it's faster and prevents mistakes

- Label all bins clearly with logical names (like A1-B2)

- Set the right user permissions — make sure people can only access what they need

In conclusion, your online store might be your business's front door, but warehouse operations are the engine

keeping everything running. As you grow, that engine needs to be efficient, automated, and

smart.

A warehouse management system transforms your operation from constantly reacting to problems into staying ahead of them. From chaotic to controlled. From a cost center to a competitive advantage. Solutions like Erply WMS show that sophisticated warehouse management isn't just about moving boxes — it's about moving your business forward with precision, efficiency, and the ability to scale.

Today's successful warehouses are smart, data-driven, and flexible. The question is: will yours be one of them?